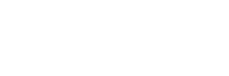

Dry screw vacuum pumps are vital components in a myriad of industrial applications, known for their ability to create vacuum environments without the use of oil or lubricants. This article aims to provide beginners with a thorough understanding of these pumps, including their principles of operation, components, advantages and disadvantages, applications, future developments, and key takeaways.

Introduction to Dry Screw Vacuum Pumps

Dry screw vacuum pumps are a type of positive displacement pump designed to generate a vacuum by moving gas through the pump using screw-shaped rotors. Unlike traditional pumps that use oil or other liquids for lubrication and sealing, dry screw vacuum pumps operate without any lubricants, making them ideal for applications that require clean and contaminant-free environments. Their ability to handle a wide range of gases, including corrosive and hazardous ones, makes them indispensable in industries like chemical processing, pharmaceuticals, and electronics manufacturing.

Basic Principles and Operation of Dry Screw Vacuum Pumps

The operation of dry screw vacuum pumps is based on the principle of positive displacement. The key elements in this process are the two screw rotors that rotate in opposite directions inside the pump casing. Here’s a step-by-step explanation of their operation:

- Gas Inlet:

- Gas enters the pump through an inlet port, driven by the low-pressure area created by the rotating screws.

- The design of the screws and their synchronize rotation ensures that gas is effectively drawn into the pump.

- Gas Transportation:

- As the rotors continue to turn, the gas is trap in the spaces between the screw threads and the pump casing.

- The rotors transport the gas along the length of the screws towards the discharge side.

- Gas Compression:

- The decreasing volume between the screw threads compresses the gas as it moves towards the exhaust port.

- This compression process increases the gas pressure, preparing it for discharge.

- Gas Discharge:

- Once compressed, the gas is expelle through the exhaust port.

- The discharge process ensures that the vacuum is maintained and that the system operates efficiently.

Components of Dry Screw Vacuum Pumps

Understanding the components of dry screw vacuum pumps is essential for appreciating their functionality and efficiency:

- Rotors:

- The heart of the pump, rotors are screw-shaped components that move gas through the pump.

- Made from durable materials to withstand harsh environments, they are designed with precise clearances to avoid contact, reducing wear and eliminating the need for lubrication.

- Timing Gears:

- These gears synchronize the rotation of the rotors, ensuring they operate in perfect harmony.

- Proper synchronization is crucial for preventing mechanical failure and maintaining efficient operation.

- Pump Casing:

- The casing encloses the rotors and forms the chamber where the gas is compressed.

- It is constructed to endure the stresses of operation, including high pressure and temperature variations.

- Inlet and Exhaust Ports:

- The inlet port allows gas to enter the pump, while the exhaust port facilitates the release of compresses gas.

- These ports are designed for optimal flow and minimal resistance.

- Seals and Bearings:

- Seals prevent leaks and maintain the vacuum integrity of the system.

- Bearings support the rotors, enabling smooth, frictionless movement and enhancing the pump’s longevity.

Advantages and Disadvantages of Dry Screw Vacuum Pumps

Advantages

- Oil-Free Operation:

- The absence of oil or lubricants eliminates the risk of contamination, making these pumps suitable for sensitive applications.

- High Efficiency:

- Precision engineering and non-contact operation result in low energy losses, providing high operational efficiency.

- Low Maintenance:

- The design minimizes wear and tear, reducing the need for frequent maintenance and extending the pump’s service life.

- Versatility:

- Capable of handling a wide range of gases, including corrosive and hazardous substances, dry screw vacuum pumps are suitable for various industrial applications.

Disadvantages

- Initial Cost:

- The advanced materials and precise engineering involved in their manufacture can make dry screw vacuum pumps more expensive upfront compared to other types.

- Complexity:

- The need for exact synchronization and precision design can make these pumps more complex to repair and service.

- Noise and Vibration:

- These pumps can generate more noise and vibration compared to other types, which may necessitate additional measures for soundproofing or isolation.

Applications in Various Industries

Dry screw vacuum pumps are use across numerous industries due to their clean, efficient, and reliable operation:

- Chemical Processing:

- Ideal for handling corrosive and hazardous gases, they ensure a clean process environment without contamination risks.

- Pharmaceuticals:

- Used in the production of drugs and other medical products, where maintaining sterile conditions is paramount.

- Semiconductor Manufacturing:

- Critical in creating the ultra-clean environments required for producing semiconductor devices.

- Food Packaging:

- Ensuring vacuum conditions for packaging without contaminating food products, thereby extending shelf life.

- Environmental Engineering:

- Applied in processes like soil remediation and vapor recovery, helping manage and mitigate environmental pollutants.

Future Developments and Innovations

The field of dry screw vacuum pumps is continuously evolving, with several promising developments on the horizon:

- Material Enhancements:

- Research into new materials that can withstand higher temperatures and more corrosive environments promises to extend pump life and reduce maintenance.

- Energy Efficiency:

- Innovations in rotor design and motor technology aim to reduce energy consumption, making these pumps more sustainable and cost-effective.

- Noise Reduction:

- Efforts to minimize noise and vibration through advanced design and materials will make these pumps more suitable for noise-sensitive environments.

- Integration with IoT:

- The incorporation of sensors and IoT technology for real-time monitoring and predictive maintenance is expect to enhance reliability and reduce downtime.

Key Takeaways

- Dry Screw Vacuum Pumps are crucial for applications requiring clean, oil-free vacuum environments.

- Basic Operation involves the synchronized rotation of screw rotors to compress and transport gas through the pump.

- Components include rotors, timing gears, pump casing, inlet and exhaust ports, and seals and bearings, each playing a critical role in the pump’s functionality.

- Advantages include oil-free operation, high efficiency, low maintenance, and versatility in handling various gases.

- Disadvantages are higher initial costs, complexity in maintenance, and potential noise and vibration issues.

- Applications span chemical processing, pharmaceuticals, semiconductor manufacturing, food packaging, and environmental engineering.

- Future Developments focus on material enhancements, energy efficiency, noise reduction, and IoT integration, promising even greater reliability and performance.

Dry screw vacuum pumps are an essential technology in modern industrial applications, offering a combination of efficiency, reliability, and cleanliness that is unmatch by other types of vacuum pumps. Understanding their operation, components, advantages, and future developments can help users make informed decisions about their implementation and maintenance.